Theory of modern purchases. Three golden rules of the buyer Which categories are suitable for collective buying

These three simple rules define the basis of the buyer's work and, despite the fact that they are simple, are the most important components of the procurement activity.

- There is no limit to low prices.

- Always improve conditions.

Let's look at them in more detail.

1. Never accept the first offer.

The first golden rule should be read as follows: "NEVER settle for the first offer." Even better: “Never take the first offer at all.” This rule is universal, should be applied in any discussion of the terms of delivery, and "never" in it is firm and absolute.

If you expected to get a price of 134 rubles for the RU-10 flange, and the supplier offers 120 rubles, what should you do? That's right, round your eyes and ask in a voice full of amazement: “Why is it so expensive?”.

You set out to demand compensation in the amount of 15% of the party, but you are offered 19%, what should you do? That's right, first of all, disagree. The second is to insist on increasing the percentage.

The first golden rule is not only about the price, but also about any terms of delivery, be it delays, compensations, bonuses, mandatory sample sizes, marketing budgets, etc. As happy as you are with the first offer, it's just unprofessional - stop without taking a single step towards improvement.

Any first proposal from a supplier can be challenged, improved and changed. This rule works 98% of the time.

It is based on the fact that in the overwhelming majority of cases the supplier's initial offer is overpriced and underpriced, taking into account possible concessions. And if you do not demand these concessions, you will receive those very high prices and low conditions.

The first rule has proven itself so firmly that it is advisable to insist on lower prices and change conditions without even looking at the offer received. And, importantly, in nine out of ten cases, these requests will be granted after the very first question about improvement.

Remember yourself. How often have you asked for and received a price reduction after the first request? I am sure that in nine out of ten cases you have reached a better price than was announced at the very beginning.

Not agreeing to the first offer does not mean demanding a price two times lower than the one announced and a delay of 365 days. The first golden rule obliges you to improve any first offer, look for ways to change it.

Any first proposal includes many components, so improving at least a few of them is an achievable task. If you refuse the first, seemingly very profitable and amazingly good offer, you may receive only 1.5% discount and (or) two days of delay. But you will never get a concession unless you start talking about it.

Not agreeing to the first offer does not mean not accepting it later, if the supplier is unshakable as a rock and does not give a penny. Rejecting the first offer doesn't mean you can't go back to it if you find yourself unable to change the offer. However, until you understand this, proceed. Demand, frown, cough with indignation, insist, firmly ask, hint, do not believe your ears. Take any appropriate steps to achieve better terms.

In my practice, in six years there were only three suppliers with whom negotiations to change the first proposal did not lead to anything. Two of them - the largest American corporations, which counted prices for a month and thought about the terms of the contract, but after they announced them - stood to the death. The third company is a Russian manufacturer of seasonal goods, with which the negotiations also did not result in an improvement in the first offer, and if we had held out for another week, he would have raised prices due to the increasing production load.

I want to note that in six years there were only three of them. The remaining several hundred improved the first proposal. We made at least a small concession on the terms of delivery, even if only by a percentage, but improved the price.

So, never settle for the first offer!

2. No limit to low prices

By itself, the term "low price" is perhaps philosophical. What price would you call low? Suppose you were told the initial price for a multi-layer bag for packaging your products is 75 rubles. You, using the first golden rule, did not accept this price and lowered the supplier's offer below 69 rubles, which, according to your data, is the average market price. As a result, after a large number of approaches in the negotiations, you settled on a price of 67.4 rubles. Suppose the supplier is no longer willing to move a single penny down. Is this a low price?

A downward price change is almost always possible and can be implemented, depending on the conditions, by a small or a very tangible percentage.

At the same time, we are, of course, interested in changing prices without compromising product quality. Just lowering the price for the sake of lowering will lead to the fact that our package will be thinner, there will be more water in the juice, less milk in sour cream, more sand in cement, cheap and brittle wood in pencils, and recycled plastic instead of alloyed steel in critical nodes, and " cardboard metal.

Price reduction can be considered as a complex consisting of several stages (Table 1).

Table 1. Stages of price reduction

| Stage | Instruments | Which vendors are best to work with? |

| 1. Finding the bottom of the price | Negotiations, methods of influencing suppliers, tenders, competitions | All suppliers |

| 2. Indirect cheapening | Pricing, reducing cost components, changing product features | Suppliers of categories A and B |

| 3. Supplier supply chain optimization | Analysis of the supply chains of the current supplier, their optimization, cost reduction in supply chains | Category A Suppliers |

| 4. Optimization of supplier supply chains | Supply chain analysis of your supplier's most significant suppliers. Optimization and cost reduction in them | Category A suppliers of your Category A suppliers |

The first step, which I call price bottoming, is solving the problem of finding the lowest price at which a supplier will still be willing to sell you their product and service (Figure 1). A characteristic sign of the found bottom of the price is the fact that the supplier is no longer ready to give a penny of a discount and refuses to deal (or the supplier is an excellent actor).

Reaching the bottom of the price is the very task that the buyer solves, bargaining, persuading, insisting, seeking a compromise, blackmailing, referring to greedy management, company standards and making other attempts.

For a supplier, a price bottom is the minimum cost at which it is still profitable for him to sell his product or service to you. For example, this may be the minimum level of profitability, which is laid down as the main pricing factor. In the example under consideration, this can be, say, a profitability (margin) of 19% at a cost of 54.6 rubles.

It is important to know that in different situations, in different conditions of inventory and demand for products, in case of fulfillment or non-fulfillment of the sales plan, the price bottom announced by the same supplier may be different.

Rice. 1. The first stage of price reduction

The first stage is largely based on the buyer's ability to negotiate. The results depend on communication skills, the ability to convincingly argue and persuade the supplier to his point of view. But this is not a complete list of the buyer's competencies necessary to reach the bottom of the price. To the most important skill, I consider the ability of the buyer to properly present (sell) himself to the supplier.

The ability to sell oneself correctly is something that a professional supplier usually comes to on his own, after a long time from the start of work. This is an experience that is acquired rather intuitively. The ability of a buyer to sell himself is a critical competency required when building relationships with complex suppliers who have a unique offer or offer the best conditions compared to competitors in the market.

The second stage I call "indirect cheapening". It includes a set of activities that are carried out jointly with the supplier and the result of which is the cumulative reduction in procurement costs (Fig. 2). First of all, such activities boil down to obtaining a price calculation, decomposing the cost of the product into components and changing each of them. Ultimately, joint work with the supplier leads to the fact that the cost of the product is reduced, which means that while maintaining the minimum profitability of the supplier, it is possible to further reduce the price.

Rice. 2. The second stage of price reduction - indirect price reduction

In our example, at the second stage of cost reduction, it will be necessary to understand what share of the cost of the manufactured package is occupied by raw materials (paper, polypropylene and polyethylene), what share falls directly on the manufacture of the package, what are the logistics costs, what are the costs of packaging the finished product, etc.

Once the cost components of the purchased package are known, work begins with the supplier to change each of them in order to obtain an overall cumulative cost reduction.

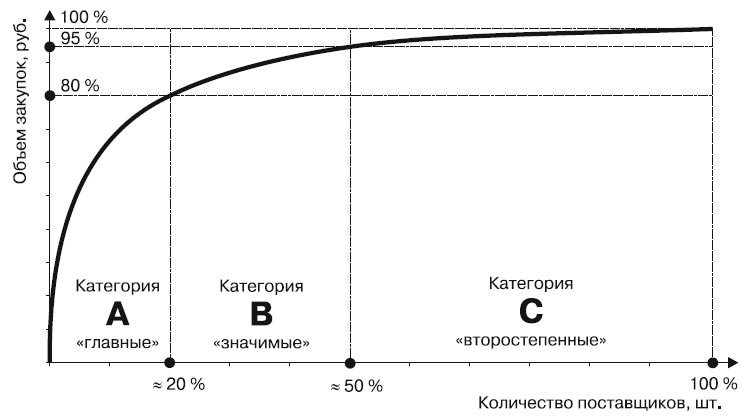

I note that the second stage of price reduction is appropriate in the case of joint work with the supplier on it. Therefore, for indirect price reduction, the most promising will be suppliers of categories A and B (see Fig. 3), that is, they provide about 95% of the volume of purchases in monetary terms, they are about 50% of the total number of suppliers.

Rice. 3. Schedule of ABC analysis of suppliers depending on the volume of purchases

If the work to reduce the price of the supplier was carried out professionally at the first and second stages, then you have reached the bottom of the price, and then lowered the bottom itself. In this case, you can say with full confidence that you got a really low price.

But what if both of these stages have been passed and the effectiveness of the second stage does not imply significant changes in the product and, accordingly, its cost?

In these cases, it will either be necessary to recognize that the lowest possible price has been obtained, or to move deeper into the supply chains in order to look for opportunities for optimization and cost reduction not in the purchased product itself, but in all stages that it goes through: from the extraction of all types of raw materials used to production. finished products by your suppliers.

The third step involves analyzing your supplier's supply chains. The essence of this process comes down to working with suppliers of category A to reduce the costs associated with the production of products you purchase.

For example, for the bags we are considering, together with the supplier, the task of analyzing its supply chains of paper, polypropylene and polyethylene, from which they then produce a multilayer bag, can be solved. The result of such an analysis may be changes in the characteristics of the paper purchased by your supplier, a change in the supplier of polypropylene, the choice of a new brand of polyethylene, a change in the methods of transporting paper to the supplier, a transition to the supply of polyethylene in rolls of a larger size with a decrease in the cost per linear meter, transfer by your supplier to outsourcing the production of group packaging etc.

As an example, Mars organizes various training events to help supply farmers and regularly hosts the Mars Ambassador Program. Ambassadors help farmers improve agricultural practices, develop training programs, monitor the state of the environment and implement many other projects. As a result, Mars improves the reliability of supply, increases supplier loyalty, reduces the cost of primary raw materials to reduce the cost of chocolate.

The above examples of joint work are appropriate when the share of purchases from a supplier is large enough. The implementation of the mutual interests of the two parties in such relationships leads to the fact that the supplier does not make secrets from his cost, and the buyer does not "squeeze" the last penny from the profit. The result is integration and a truly mutually beneficial set of measures to reduce the cost of producing the product that matters to you.

If the third stage is implemented, then the next step will be joint, sometimes tripartite, work to optimize and reduce costs in the supply chains of your suppliers' suppliers.

In the example under consideration at the supplier of multilayer bags, the result of the work may be a change in the manufacturing technology by his supplier of polyethylene: the use of additives from another manufacturer in the production, and, consequently, a decrease in the thickness of polyethylene with increased gloss and similar strength.

The fourth stage is expedient only in the case of key suppliers and the most costly procurement components.

The first stage of price reduction is the simplest and most common way to save on purchases. Its effectiveness directly depends on the buyer's ability to negotiate, negotiate, and organize tenders. The skills of buyers in this case need to be strengthened, for example, through internal training (mentoring) or external training (trainings).

The second stage of price reduction is more difficult, while the third and fourth seem extremely difficult for the vast majority. However, if your company is interested in increasing the competitiveness of its products, you will be forced to sequentially come to the second, third, and fourth stages of price reduction. In European practice, this has long been the norm, while for Russian business it is rather an exception. But the Russian market every year takes more and more steps towards the transparency of supply chains, and hence to the possibilities of optimizing the most significant of them.

A professional buyer knows that there is no limit to the work on price reduction. If you have received all possible seller discounts, then you still have many options for reducing costs in all supply chains, not only your own, but also your suppliers.

3. Always improve conditions

What terms of delivery do you improve when working with suppliers? Let's remember them.

Usually, the first thing that comes to mind is the volume of the purchase, the price, the deferred payment, then the delivery. There is a pause, and the recollection continues with an effort: what else do I need from the supplier, what can I improve. After a while, they remember fines, bonuses, guarantees, etc.

Most negotiations with a supplier do not initially discuss more than four terms of delivery. Even such a stable expression appeared - “to wander in four and a half Christmas trees” (Fig. 4).

"Half of the Christmas tree" is the quality of the purchased products. It means that if the quality of the product does not meet your requirements, then it is pointless to discuss anything else.

Rice. 4. "Four and a half trees" of the terms of cooperation

Of course, the price, delay, delivery and volume of purchases are the most important parameters of any transaction, but we must not forget that, in addition to them, there are more than 100 factors that determine the expediency and profitability of working with a supplier.

Finding out why, apart from volume, price, delay and delivery, no other conditions were discussed with the supplier, you can encounter awkward silence. The buyer easily remembers what conditions he needs from the supplier, but when it comes to actual negotiations, there is some kind of eclipse and, in addition to the “four trees” described above, in the vast majority of cases, other conditions are not remembered.

In justification, they say that they forgot, that there was no time, that the situation is not right, and they give other not the most convincing arguments. In some cases, the buyer simply does not realize what other conditions he can negotiate with his supplier.

The conditions that a buyer can and should work out when discussing a contract or delivery are multifaceted and depend on the specifics of the business and the product or service being purchased. However, we must keep in mind that there are always more than four and a half conditions!

Let's look at what conditions we can negotiate with the supplier.

On fig. 5 shows 37 groups of factors that influence the choice of a supplier, the terms of cooperation and the total cost of a product or contract. For your particular case, about 20 groups may be relevant - this is exactly what you are able to work out as part of improving the terms of delivery.

Rice. 5. Factors determining working conditions and choice of product supplier

Each of the groups of factors makes it possible to achieve final savings from hundredths of a percent to several percent on each of them. Thus, having worked out the improvement of conditions throughout their set, you can achieve savings that are completely unattainable in the case of direct attempts to "bargain" the supplier.

Now let's focus on the word "always" in the name of the third golden rule. It is always necessary to improve the conditions. Let's see how you can do this.

With each renewal of the contract. I hope that in your company the contract is concluded for one year from the date of signing, for example, from July 27, 2017 to July 27, 2018. It is bad if it is signed from the current day until the end of the calendar year, that is, until December 31. In the case when the contract is concluded from December 31 to December 31, but is not extended, but signed anew, at the end of the year, buyers have an emergency for their extension. Then, there is usually no talk of any improvement in conditions with suppliers. For the buyer, the main thing in this case is simply to hand over the new contract to the financial service on time and put a tick in the register of documents.

If the contract with the supplier is automatically renewed, no work is being done to improve the conditions.

If the contract is signed from the date of conclusion for a year, the buyer has the opportunity every month to plan work to improve conditions with companies for which the contract will be extended in the near future. Without rush and turmoil, every year improving the conditions of supply at least for several factors.

At every meeting. If you have regular but infrequent meetings with suppliers, then discussions on improvements to terms of delivery can be held at every meeting. So by sticking to the schedule of meetings, you will get a continuous array of negotiations for better conditions. And do not forget that even if your conditions are rigidly fixed by a contract for a year, in order for them to change, they must be discussed in advance.

In relation to the supplier category. For example, in January and February, you work with category A suppliers - work on improving the conditions for them. In March, negotiate with the first third of category B suppliers, in April and May you complete category B. June is the month for working with the largest suppliers of category C. In July, this cycle repeats.

Depending on the conditions. For example, in January, all suppliers are working out an increase in the deferred payment, in February, negotiations are underway to increase the insurance inventory of the supplier, in March, penalties are discussed, in April - the supplier's marketing activities, in May - training of your employees, etc.

Own plan for each supplier. For each supplier, a "ladder" is planned for the year (Fig. 6) - a list of conditions that need to be worked out and that need to be changed. The end result of this "ladder" is to bring the terms of cooperation to a pre-created "ideal" portrait of the supplier. For example, in January - an extension of the guarantee, in March - an increase in commodity credit, in April - a discount for the assortment, in June - a revision of penalties, etc.

Rice. 6. Plan for changing conditions at the supplier

A professional buyer, having determined a complete list of commercial conditions that he can and should improve for his company, regularly works to improve them.

So, once again we repeat the three golden rules of the buyer, which should be fundamental in the work.

- Never accept the first offer.

- There is no limit to low prices.

- Always improve conditions.

According to the ABC analysis, category A suppliers provide 80% of the volume of purchased products, they are approximately 20% of the total number of suppliers. Suppliers of category B provide 15% of the volume of purchases, they are about 30% of the total number of suppliers. Suppliers of category C provide 5% of the volume of purchases, and they are about 50% of the number of suppliers (Fig. 3). |

|

Outsourcing (from the English outsourcing) is the transfer by a company of any of its activities or the functioning of another organization specializing in this area. Unlike a one-time appeal to an organization specializing in a narrow field, outsourcing involves the conclusion of a long-term contract for the provision of work or services. For example, full accounting, recruitment, HR administration, IT support, security, logistics services, etc. |

From the book "Purchases for 100%"

| Name of the seminar, training, course | Feb | Mar | Apr | May | Jun | Jul | Price, rub. |

Every business owner is well aware that purchasing is one of the most important levers in the success of the company. It is in connection with the significance of this process in the results of entrepreneurship that due attention should be paid to the study of this industry.

Procurement is the main step that directly affects the level of profitability from doing business and the success of business development. Every moment associated with the acquisition of goods for the company's work must be considered and analyzed.

What is a purchase

Everyone can abstract the meaning of this word. However, business is not a place where approximate definitions and meanings will fit. In business vocabulary, purchasing is the acquisition of goods in large quantities for the company's activities.

Most often, purchases are made in bulk, because it is more profitable and more convenient for the continuous operation of the company, no matter what the company does. Also, to check the level of demand for a product, retail units are sometimes ordered.

What is public procurement

There are many types of purchasing goods. Public procurement is the acquisition of the necessary goods and services for the full fulfillment of the obligations of the heads of the country to the population.

The state can acquire everything that is necessary at the expense of budgetary funds. It can be:

- Transport.

- Cleaning equipment.

- Emergency vehicles.

- Medicines for state medical institutions.

- Materials and equipment for construction.

This is just a small list of purchases that can be carried out by public authorities. In general, the head of state or authorized persons can order goods and services that are important for the full-fledged activity for budgetary funds.

What types of purchases are

Regardless of what type of activity the company is engaged in, in any case, procurement is an integral part for successful work. In turn, purchases are divided into two types:

- Direct.

- Indirect.

Direct purchase is the direct purchase of goods or services related to the activities of the company. This can be finished products, as well as elements for the implementation and creation of new sources of production.

Under direct purchases is meant the ordering of goods, services from supplier companies for the purpose of full-fledged activity of the enterprise.

Indirect procurement is what is needed in the work, but is not directly related to the company's activities. For example, stationery, office interior items, accessories for organizing space. These purchases are also very important, because without them it will not be possible to fully equip staff workplaces and communication with customers.

Each species has its own procurement system. Depending on whether the company is private or public, this scheme may differ. Private offices can conduct the process of ordering goods and services directly with the supplier. That is, without using additional tools and programs, firms can contact the seller of the necessary resources by phone or by e-mail.

In the case when the purchase is carried out at the expense of the state budget, the procurement scheme varies. In this case, it is not possible to negotiate deliveries directly with the seller of the necessary goods or services. Since 2013, an electronic trading system has been introduced. Such a scheme was invented in order to exclude corruption from the legislative state authorities. Unfortunately, there were precedents, so the responsible authorities for the fight against corruption in the state found a method to reduce the level of waste of the country's money.

With the introduction of electronic trading in the public procurement system, the ordering system has become transparent and accessible to everyone. Even an ordinary citizen in this program can view all acquisitions in the state.

What to focus on when making purchases

When making purchases, it is worth considering some factors:

Proper purchases will help in the successful conduct of business, no matter what the company does.

I started my career in 2003 at the Bosch Automotive Components Plant and worked my way up from trainee to regional manager.

I will clarify the scope of responsibility for Bosch indirect purchases. We are responsible for materials that are not included in the final product and all services, works, equipment that we order from suppliers. I can say for sure that such purchases have never received such attention as now. Usually, the focus has always been on direct procurement due to its large purchase volume and direct impact on the quality of the product, but after a deep analysis of indirect procurement, assessing the potential in economic effect, the management immediately decided to implement a project to restructure indirect procurement and change processes for them. more efficient work.

I like one expression: "Change creates opportunities." I think that it is the best suited to the topic of this article and the situation that has developed at the moment in our country. But back to our topic.

As a result of the project, we have become one global team with standard processes, common goals, and results. The project implied the standardization of processes at the global level with the minimum necessary adaptation to the peculiarities of the legislation of different countries.

For me and for other participants, this project provided an excellent opportunity for development. Considering the complexity of the project, it was possible to use such a chance only with positive thinking, using a constructive approach.

The main reason for the change was the realization of the enormous potential for savings from the global pooling of needs. The first experience was in Germany - the management of several plants decided to combine the needs and go with this volume to the supplier for negotiations, which led to an excellent result. The so-called "win-win" situation, which is probably the dream of all managers in the world.

Gradually, a global procurement structure was organized and focused on large global projects. At the time of the project implementation, 44% of the volume of global suppliers, mainly at the expense of Germany, had already been merged. Additional analysis showed that there is still approximately the same potential in other countries of the world. By combining not only the needs of global suppliers, but also the realization of cross-regional and local potential.

The second main reason is staff development. Previously, procurement specialists were responsible for different categories. They did not have an understanding of the market in the entire region. Negotiating positions were often weak due to little need for materials or services in one particular plant. Most of you are probably familiar with this situation. Each location independently decided how to develop staff and what tasks to entrust them with. Tasks that are often not the direct responsibility of the buyer and are constantly changing. But more on that later.

As a result of staff development, we have made purchasing specialists truly specialists who are responsible for purchasing in a certain area, regardless of their location. For example, specialists in the procurement of logistics services are located in Moscow and serve, including factories in Samara and Engels. And at the moment I can say that my specialists have developed to a higher level - they are starting to work with regional volumes and clients in Eastern Europe.

In 2011, an analysis of the current state of disparate regional organizations was carried out and a decision was made to create an independent regional structure. A structure independent of the management of local organizations and subordinate to Corporate Purchasing with its own budget.

Within this framework, the Bosch Auxiliary Purchasing world has been divided into 10 regions. Russia and the CIS countries belong to Eastern Europe with the head office in Budapest. There is my immediate supervisor, who sets goals for me and to whom I submit functionally. The boundaries that were tied to the leader on the spot have been erased. The structure has become virtual, although from a purely legal point of view, we report directly to the legal entity on which we are located.

As I said at the time of the appearance of the regional structure, the global structure of corporate procurement already existed. It is located in Stuttgart.

After the creation of a new regional structure at the end of 2012, these two virtual organizations began to actively interact.

Each structure individually had its own strengths and weaknesses, but as a result of the interaction, we got a powerful procurement organization that has knowledge of the global market, with its own regional specifics.

From global procurement, we take experience, processes and methods, and from the regions we provide knowledge of the laws, the characteristics of internal customers, local suppliers and provide operational support for the implementation of the global strategy.

Perhaps, some will say that it was possible to combine needs without forming a new regional structure, but, as previous experience has shown, this is not effective, because it is not clear who is specifically responsible for the result and it is difficult to set goals for someone who does not report to you.

It is worth saying here that direct and indirect purchases at Bosch are two completely different worlds - different requirements for quality, supplier development, etc.

Naturally, with such a merger, there should be uniform standard rules for interaction and procurement processes that are carried out using the IT system. The rules and processes have been developed and hosted in a single portal called Compass.

The portal is an intranet page with links to processes and instructions. On the left is a link to the global structure, on the right to regional processes. Below is a link for internal customers. When you click on the link, only the information that is intended for the internal client appears. On the right there are additional links to instructions, signature regulations, trainings, etc.

If you ask a buyer in Germany, Hungary, Brazil or Russia about any process, they will tell you about the same thing. With such an organization of processes, the prerequisites for effective management and international development of employees are created.

Here I would also like to note the new regulation of the right to sign. Using the standard process of coordinating decisions on the new signature regulation, the manager does not have to be present locally at the enterprise or in the office. Signing the contract physically becomes just a formality. Decisions are coordinated electronically with the heads of the relevant procurement categories, who may be located anywhere.

As a result of a clear structure for describing processes (and not only purchasing, but also accounting and warehouse, as they directly intersect with purchases), we managed to very accurately delineate responsibilities between departments and improve the efficiency of interaction within the company.

I will not dwell on the description of the processes, but I will note the main types of orders that we offered to our internal client.

They allow, when expanding the business (construction of new offices, factories), not to expand the procurement staff. I don't think it's necessary to mention that personnel costs are the biggest in the budget. Let's take a look at a highly simplified diagram of the regular ordering process and the automatic (eCat and mini order) process.

Usually, an internal client creates an application, then, after approval, the application goes to the buyer, who creates an order, sends it to the supplier, after shipment or provision of services, the invoice was checked by the buyer and then the invoice was paid based on the order in the system.

With automatic ordering, the role of the buyer was excluded at the stage of creating an order and at the stage of checking the invoice.

In this case, the application is created in the electronic catalog or a regular one, but up to a certain amount. Prices are fixed in the catalog and after agreement with the manager, the order is created in the system automatically and sent to the supplier. The same for a mini order, but for small needs that are not in the catalog.

According to our instructions, the reconciliation of the invoice received as a result with the order in the system should be carried out by the accounting department.

The condition under which this type of order is possible is complete transparency in the IT system of the movement of the application from the moment of creation to payment.

Procurement deals with procurement.

Logically, but in fact, in many companies this is not the case.

Sorry, this material is available in its entirety only to members of the Community of Production Managers.

You can register and get access to exclusive analytical, methodological and translated materials published on the site.

Participation also provides many additional opportunities.

Procurement specialist and partner of the Swiss company Siegel in Ukraine and the CIS, Marina Trepova, at a master class at the Edinburgh Business School, spoke about how to optimize purchases in a company during a crisis

About the role of procurement in the company

There are two ways to increase a company's profits: by increasing sales or by reducing expenses. For example, in order for a company to increase profits from $70 million to $75 million, sales would have to increase by $54 million. Those who have dealt with sales know that it is quite difficult to achieve such a figure, for this it is necessary to make a breakthrough worth a lot of effort. If you try to achieve the same profit margin by reducing costs, then we will talk about reducing purchases by only 5%. For a professional buyer, this is nonsense. A 5% reduction in purchases is the minimum we can talk about. Thanks to various tools, the buyer can reduce costs from 5 to 30%.

According to a study by British colleagues from the Proxima Group, who interviewed the largest companies regarding the impact of indirect procurement on company operations and cost optimization, it turned out that 70% of companies believe that indirect procurement is very important for strategic business partnerships, but at the same time they are paid little attention.

About buyers

Everyone is familiar with the terms "purveyor", "supply department". They came to us from the USSR. Now there are also supply departments and suppliers. Their main role is to ensure the uninterrupted production of goods and services. But they do not carry out strategic tasks. And the term "buyer" appeared in our country in the late 1990s - early 2000s. Buyers grew out of suppliers. The buyer fulfills the same role, but with some innovations that have come to us from the West. Now we say that these are professionals who bring additional value to the company. We are talking about the role of buyers as strategic partners: they actively influence the business, get involved in it and bring additional profit and value through strategic decisions. Their function is implemented not when everything has already been decided - “here's a plan for you, go buy”, but precisely at the early stages of strategic planning, decision-making - to produce on your own or buy, do it yourself or outsource, etc. In Ukraine, this is just beginning to develop, we are 5-10 years behind Europe and America.

What knowledge does a professional buyer need? For a long time in the first place was the ability to negotiate. But as a result of a study by Western colleagues in 2012, it turned out that it fell to the second step, and category management, analytical skills and the ability to approach strategically came to the first.

Risk management and minimization is one of the functions of a professional buyer. He must understand what risks he may face, firstly, in the contractor's market, and secondly, in the market where the company sells its goods and services. The buyer must manage both. With a strategically important contractor, the buyer must discuss his risks and control what he does in order to avoid an unforeseen situation. It is very difficult, for this you have to have a very close relationship.

The buyer is such a very political profession.

The buyer's job is jewelry, because he must reduce the company's costs without harming the business.

About procurement

In English, there are two words that, when translated into Russian, mean “purchases”: purchasing and procurement. Purchasing - refers primarily to the technical, supply aspect of procurement. Procurement is the strategic part.

The procurement process must necessarily fit into the overall strategy of the company. Otherwise, it will be chaotic, episodic.

There are different classifications of purchases. I want to dwell on such a division of purchases into direct and indirect. Direct - all those involved in the process of production of goods and services. Indirect purchases are everything that concerns the maintenance of the office, employees: marketing, logistics, car fleet, stationery, medical insurance, IT, travel expenses, travelling, etc. They do not fall on the cost of production, but the potential for their optimization is huge.

In indirect procurement, you can optimize and optimize. For example, take the purchase of logistics services. With a competent approach of the buyer to planning routes and loading pallets, you can achieve a cost reduction of at least 10%. Elementary: underutilized space, incorrectly delivered pallets - this is money thrown away. The contractor may be doing this on purpose, or may not be aware of the problem. Here, the role of the buyer is to analyze and properly plan routes and loading, as well as negotiate with the logistics provider so that he optimizes this process at your request. And speaking the language of the buyer, here we are not only talking about a price reduction by 10%, here we are talking about partnership.

Marketing is just an unplowed field for optimization. In marketing, it is very easy to hide large extra expenses.

I have outlined three approaches to the procurement process. The first is purely formal: when there is a function through which certain documents must be passed, and it will select contractors. The second is a strategic partnership: when buyers participate on an equal footing in discussing the budget for the next year, the plan, in scheduling negotiations and purchases, when internal clients come to the purchasing department and advise on how best to proceed in a certain situation. This is aerobatics in the work of the buyer. The third is outsourcing.

About outsourcing

Modern foreign companies are trying to outsource as many functions as possible, including procurement. Microsoft has outsourced almost all procurement functions.

Usually, purchasing is outsourced, but procurement cannot be outsourced.

As part of the procurement activities, various tasks are performed: negotiations, contracting, maintaining databases of suppliers, maintaining documentation and ERP systems. This requires different people. As a general rule, good strategic negotiators don't like working with software. For example, Microsoft has separate centers that deal only with maintaining information in SAP.

Outsourcing is appropriate to use in small companies where it is unprofitable to keep buyers. It is possible that outsourcing companies are specially created that accumulate a pool of customers in a certain category, which allows you to supply goods and services at the best price, with a significant discount for customers. This is very promising for Ukraine.

In no case should strategic purchases be outsourced - that is, what is needed for the production of goods and services. But administrative and office purchases are taken out immediately.

On procurement in times of crisis

What are the challenges facing the buyer in times of crisis, in times of challenge? First of all, the company's operations must not stop. This is the main task of the buyer - ensuring uninterrupted activity. So that it does not turn out that the company has only one supplier, and if something happens to him, then production stops. This situation should never happen. There should always be fallbacks. The interrupted contracts with Russia are a current case in point.

What can be done with the supplier base in a crisis? Firstly, if there are too many of them, then it is worth reducing their number to what is necessary. It is irrational to bear the costs of database management and endless tendering. It takes time and profit. Suppliers need to be reduced and consolidated. In addition, it is worth reducing even the staff of buyers so that there is one buyer in one direction, no more. If the company has several representative offices and a central office, then you need to combine suppliers - and you will get huge benefits.

About buyer tools

How to cut costs without hurting operations? To begin with, you need to use category management, with which you can significantly reduce the purchase cost of the necessary goods and services. This is a tool that allows you to intelligently, strategically manage certain categories. A category is a line of spending in a company on which a lot of money is spent and which is large enough to separately analyze the market for this type of procurement and, accordingly, develop a strategy. For example, IT services, marketing, insurance. Breaking down into categories depends on the specifics of the company.

How is category management implemented in practice? The first step is brainstorming, a strategic session of the working group, which includes the buyer, the internal client and all the company's specialists who can help in making a decision. The result of this should be an understanding of what the internal client needs and how it can be implemented in the company, identifying all risks and pitfalls. Next, the buyer conducts market research, searches for suitable contractors and works out the risks associated with them. You also need to analyze which of your current vendors could potentially complete the task. Then you need to build a kind of matrix in which to place categories and potential suppliers, draw up a specification and send out requests for tender.

Our procurement strategy depends on contractors. Through a systematic approach to working with them, risks are reduced and the value of deliveries is increased, because they provide more innovation.

Rather than holding tenders every six months, running around the market in search of a contractor who is 2 kopecks cheaper, it is better to make an effort once to find 2-3 best contractors and build partnerships with them, develop them.

But you cannot create a monopoly. The contractor must always feel that others are breathing down his neck. It is impossible to concentrate 100% of tasks on one contractor. In addition, you need to regularly remind him of tenders and ask for market analytics, cuts.

What else affects cost reduction? Electronic trading. They minimize the risks of bias, informal arrangements, etc. This, in turn, encourages suppliers to lower their prices. Not everything can be carried out through electronic trading, but where possible, this must be done.

Each employee must be briefed on the procurement policy and report on it. This is a normal, healthy, adequate bureaucracy that helps to avoid problems.

The calendar of negotiations and purchases is very important from the point of view of systematization and strategy. This is a platform for a constructive dialogue with the internal client and all parties involved.

Procurement specialist and partner of the Swiss company Siegel in Ukraine and the CIS, Marina Trepova, at a master class at the Edinburgh Business School, spoke about how to optimize purchases in a company during a crisis

About the role of procurement in the company

There are two ways to increase a company's profits: by increasing sales or by reducing expenses. For example, in order for a company to increase profits from $70 million to $75 million, sales would have to increase by $54 million. Those who have dealt with sales know that it is quite difficult to achieve such a figure, for this it is necessary to make a breakthrough worth a lot of effort. If you try to achieve the same profit margin by reducing costs, then we will talk about reducing purchases by only 5%. For a professional buyer, this is nonsense. A 5% reduction in purchases is the minimum we can talk about. Thanks to various tools, the buyer can reduce costs from 5 to 30%.

According to a study by British colleagues from the Proxima Group, who interviewed the largest companies regarding the impact of indirect procurement on company operations and cost optimization, it turned out that 70% of companies believe that indirect procurement is very important for strategic business partnerships, but at the same time they are paid little attention.

About buyers

Everyone is familiar with the terms "purveyor", "supply department". They came to us from the USSR. Now there are also supply departments and suppliers. Their main role is to ensure the uninterrupted production of goods and services. But they do not carry out strategic tasks. And the term "buyer" appeared in our country in the late 1990s - early 2000s. Buyers grew out of suppliers. The buyer fulfills the same role, but with some innovations that have come to us from the West. Now we say that these are professionals who bring additional value to the company. We are talking about the role of buyers as strategic partners: they actively influence the business, get involved in it and bring additional profit and value through strategic decisions. Their function is implemented not when everything has already been decided - “here's a plan for you, go buy”, but precisely at the early stages of strategic planning, decision-making - to produce on your own or buy, do it yourself or outsource, etc. In Ukraine, this is just beginning to develop, we are 5-10 years behind Europe and America.

What knowledge does a professional buyer need? For a long time in the first place was the ability to negotiate. But as a result of a study by Western colleagues in 2012, it turned out that it fell to the second step, and category management, analytical skills and the ability to approach strategically came to the first.

Risk management and minimization is one of the functions of a professional buyer. He must understand what risks he may face, firstly, in the contractor's market, and secondly, in the market where the company sells its goods and services. The buyer must manage both. With a strategically important contractor, the buyer must discuss his risks and control what he does in order to avoid an unforeseen situation. It is very difficult, for this you have to have a very close relationship.

The buyer is such a very political profession.

The buyer's job is jewelry, because he must reduce the company's costs without harming the business.

About procurement

In English, there are two words that, when translated into Russian, mean “purchases”: purchasing and procurement. Purchasing - refers primarily to the technical, supply aspect of procurement. Procurement is the strategic part.

The procurement process must necessarily fit into the overall strategy of the company. Otherwise, it will be chaotic, episodic.

There are different classifications of purchases. I want to dwell on such a division of purchases into direct and indirect. Direct - all those involved in the process of production of goods and services. Indirect purchases are everything that concerns the maintenance of the office, employees: marketing, logistics, car fleet, stationery, medical insurance, IT, travel expenses, travelling, etc. They do not fall on the cost of production, but the potential for their optimization is huge.

In indirect procurement, you can optimize and optimize. For example, take the purchase of logistics services. With a competent approach of the buyer to planning routes and loading pallets, you can achieve a cost reduction of at least 10%. Elementary: underutilized space, incorrectly delivered pallets - this is money thrown away. The contractor may be doing this on purpose, or may not be aware of the problem. Here, the role of the buyer is to analyze and properly plan routes and loading, as well as negotiate with the logistics provider so that he optimizes this process at your request. And speaking the language of the buyer, here we are not only talking about a price reduction by 10%, here we are talking about partnership.

Marketing is just an unplowed field for optimization. In marketing, it is very easy to hide large extra expenses.

I have outlined three approaches to the procurement process. The first is purely formal: when there is a function through which certain documents must be passed, and it will select contractors. The second is a strategic partnership: when buyers participate on an equal footing in discussing the budget for the next year, the plan, in scheduling negotiations and purchases, when internal clients come to the purchasing department and advise on how best to proceed in a certain situation. This is aerobatics in the work of the buyer. The third is outsourcing.

About outsourcing

Modern foreign companies are trying to outsource as many functions as possible, including procurement. Microsoft has outsourced almost all procurement functions.

Usually, purchasing is outsourced, but procurement cannot be outsourced.

As part of the procurement activities, various tasks are performed: negotiations, contracting, maintaining databases of suppliers, maintaining documentation and ERP systems. This requires different people. As a general rule, good strategic negotiators don't like working with software. For example, Microsoft has separate centers that deal only with maintaining information in SAP.

Outsourcing is appropriate to use in small companies where it is unprofitable to keep buyers. It is possible that outsourcing companies are specially created that accumulate a pool of customers in a certain category, which allows you to supply goods and services at the best price, with a significant discount for customers. This is very promising for Ukraine.

In no case should strategic purchases be outsourced - that is, what is needed for the production of goods and services. But administrative and office purchases are taken out immediately.

On procurement in times of crisis

What are the challenges facing the buyer in times of crisis, in times of challenge? First of all, the company's operations must not stop. This is the main task of the buyer - ensuring uninterrupted activity. So that it does not turn out that the company has only one supplier, and if something happens to him, then production stops. This situation should never happen. There should always be fallbacks. The interrupted contracts with Russia are a current case in point.

What can be done with the supplier base in a crisis? Firstly, if there are too many of them, then it is worth reducing their number to what is necessary. It is irrational to bear the costs of database management and endless tendering. It takes time and profit. Suppliers need to be reduced and consolidated. In addition, it is worth reducing even the staff of buyers so that there is one buyer in one direction, no more. If the company has several representative offices and a central office, then you need to combine suppliers - and you will get huge benefits.

About buyer tools

How to cut costs without hurting operations? To begin with, you need to use category management, with which you can significantly reduce the purchase cost of the necessary goods and services. This is a tool that allows you to intelligently, strategically manage certain categories. A category is a line of spending in a company on which a lot of money is spent and which is large enough to separately analyze the market for this type of procurement and, accordingly, develop a strategy. For example, IT services, marketing, insurance. Breaking down into categories depends on the specifics of the company.

How is category management implemented in practice? The first step is brainstorming, a strategic session of the working group, which includes the buyer, the internal client and all the company's specialists who can help in making a decision. The result of this should be an understanding of what the internal client needs and how it can be implemented in the company, identifying all risks and pitfalls. Next, the buyer conducts market research, searches for suitable contractors and works out the risks associated with them. You also need to analyze which of your current vendors could potentially complete the task. Then you need to build a kind of matrix in which to place categories and potential suppliers, draw up a specification and send out requests for tender.

Our procurement strategy depends on contractors. Through a systematic approach to working with them, risks are reduced and the value of deliveries is increased, because they provide more innovation.

Rather than holding tenders every six months, running around the market in search of a contractor who is 2 kopecks cheaper, it is better to make an effort once to find 2-3 best contractors and build partnerships with them, develop them.

But you cannot create a monopoly. The contractor must always feel that others are breathing down his neck. It is impossible to concentrate 100% of tasks on one contractor. In addition, you need to regularly remind him of tenders and ask for market analytics, cuts.

What else affects cost reduction? Electronic trading. They minimize the risks of bias, informal arrangements, etc. This, in turn, encourages suppliers to lower their prices. Not everything can be carried out through electronic trading, but where possible, this must be done.

Each employee must be briefed on the procurement policy and report on it. This is a normal, healthy, adequate bureaucracy that helps to avoid problems.

The calendar of negotiations and purchases is very important from the point of view of systematization and strategy. This is a platform for a constructive dialogue with the internal client and all parties involved.